Due to the limited production and vast selection of options to chose from, we do not have Claude Dozorme available to purchase on line at this time. Please come into the store, call us or email us and we will be happy to help you find the right style, color and material for a beautiful cheese set, steak knives, corkscrew or carving set.

What you need to know:

The story began in 1902 in La Monnerie, close to Thiers. Blaise Dozorme, an expert steel worker, decided to use his expertise to create a small knife-making workshop in his home. Working mainly as a subcontractor, his professionalism and keen sense of duty gained him a certain notoriety in the Thiers basin. His entrepreneurial spirit coupled with a dominant personality resulted in his peers naming him "The Wolf". A few decades later, the Dozorme firm would use this nickname as the basis for its logo.

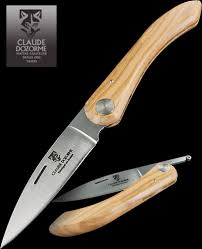

FROM FATHER TO SON …Taken over by his son Valentin in 1934, the small workshop gradually made a name for itself, further anchoring its expertise and leaving its mark in the cutlery sector of the Thiers region. The family business really began to develop on a larger scale. Claude, the grandson, decided to invest massively in tools and mechanization in a drive to expand and develop the business. The Claude Dozorme brand was born at the beginning of the 1980’s as was their first creation: the first Laguiole non-folding table knife. Henceforth, the pioneer of these manufacturing techniques, officially awarded the title Maître Artisan Coutelier, would strive to continuously develop the brand.

AND NOW TO DAUGHTER ... There was a new development in 1991 when Claudine Dozorme, Claude Dozorme’s daughter, took over the reins of the family business. In 1984, after completing her post graduate studies, she joined the Kraft General Foods agri-foods group as sales manager. She stayed at Kraft until 1991 when her father asked her to help him develop his brand. She thus took charge and marketed Claude Dozorme knives to various distributors and ran a France-wide sales team. Development of the brand, integration of new manufacturing processes, creation of catalogues and sample products, strategic thinking on new models and materials… The arrival of this vivacious young woman would revolutionize the small family business.

THE PROCESS ... Once the steel has been cut, the blades take their long journey to completion. The steel first undergoes a dual heat treatment, quenching, a high-precision operation that strengthens the blade’s mechanical properties and modifies the steel’s molecular composition. The blade then goes on to the hardness test, followed by grinding. This step, which consists in grinding the blade to refine it, gives the future blade its long life, a durable sharp edge, the quality of its cutting power and the possibility of re-sharpening the blade several times after use. This is why the Claude Dozorme firm takes exceptional care over the grinding step in particular (blade grinding). The blade then goes to the polishing workshop to be given its brilliant, shiny finish.

The next steps are to shape and then polish its handle (wood, horn, shagreen, leather or even plexiglass, the possibilities are endless) using sisal and cotton disks that enable the bolsters and handle to be perfectly adjusted. Once the handle has been perfectly formed, it has to be buffed to give it its smooth, shiny appearance. Final sharpening -gives the perfect cutting edge. In all, there are over 45 stages in making a knife, several of which are still manual and highly artisanal effect for any and every occasion.